blown film machine pdf

However a review of the process of blown film extrusion is worthwhile. 51 Introduction to Blown Film Extrusion.

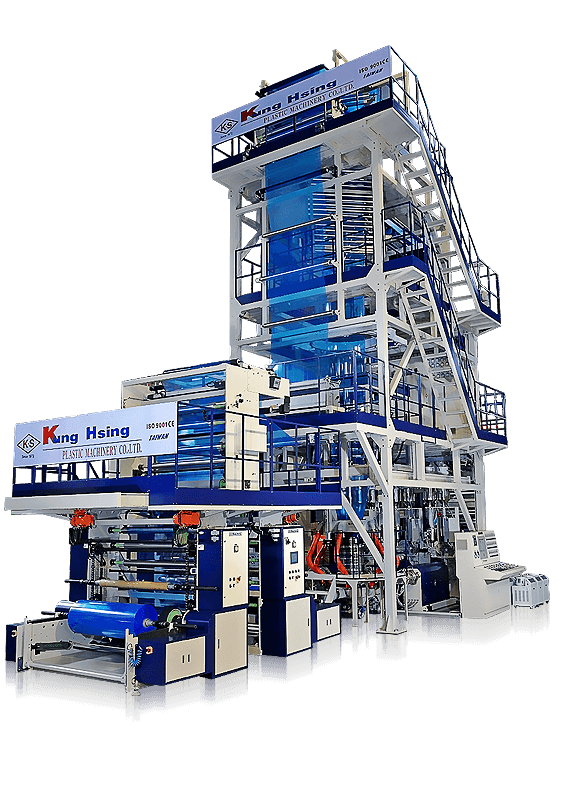

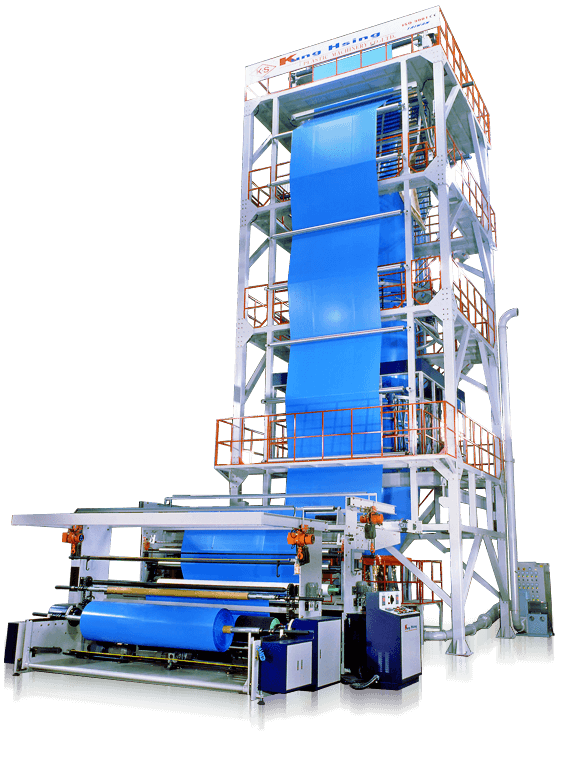

Kung Hsing Plastic Machinery Co Ltd Prm Taiwan B2b Marketplace

Single Screw Plastics Extruder R B Plastics Machinery The most common ones today are the combination of a 45mm extruder together with a garbage bags normally a 55mm outer layer normally 12-20.

. Working of Blown Film Extrusion Machine Units Components Purpose Pallet feeding unit Material conditioner. Processing our understanding of the extrusion of tubular blown film remains in the stage of art. In these models variations of the physical variables across the thin film are neglected leaving the vari-.

Machine Construction A cut-away drawing of a simple single screw machine is shown in Figure 1. Kirk Cantor Pennsylvania College of Technology Williamsport PA USA Distributed in the USA and in Canada by Hanser Publications 6915 Valley Avenue Cincinnati Ohio 45244-3029 USA Fax. SINGLE PLATFORM MONO LAYER BLOWN FILM MACHINE Main Motor Model Suitable Material Screw Dia.

Pearson and Petrie and others have developed steady-state models to describe the blown film extru- sion process in the limit of very thin films 1 1 12. An operator can become so familiar with a given film line that problems are solved intuitively but training new. Machine Direction Asymmetrical MD Wrinkle Processing Conditions Asymmetrical MD Wrinkles TD gauge variation insufficient web tension between idler rollers Equipment insufficient traction on idler rollers bent idler rollers idler roller bearing not rotating properly Film Tension Bands May be caused by Too much film.

38 shows a photograph of a nine layer blown film production machine 6. Blown Film Machine Optional Devices. Blown film machine pdf Thursday May 19 2022 Edit.

The blown film extrusion process can produce magnificent arrays of products however. The bottleneck in blown film extrusion lies in the cooling of the fast moving thin melt film It is important to understand that three elements of the blown film process are of first order importance to be able to produce near uniform gauge blown. A a three layer die and B a five layer die 5.

WH blown film lines are designed especially for the flexible packaging industry. By continuously removing the melt film over the barrier flight the solid bed surface remains intact. State of the art.

51 Introduction to Blown Film Extrusion. 100 600mm Die gap. 40 mm to 80 mm diameter Die opening.

T h e b l ow n fi l m p ro c e s s. 08 28 mm Bubble diameter BUR blow up ratio. Screw carbonization and frequent dye cleaning caused by oxygen in the feed throat hopper are issues with blown film extrusion that can be improved or eliminated by using a nitrogen purge.

Blown film extrusion is also used in the manufacture of products from PVC. PVC is an amorphous polymer glass transition temperature 220 F 105 C. Given therefore a single screw machine is being described that has a screw of diameter 60 mm and a length of 24 screw diameters that is a LD ratio of 241.

2 45 DDR draw down ratio gap widththickness x BuR MD machine direction TD transverse direction LD ratio of screw. 6 250 microns Layflat width. The most common ones today are the combination of a 45mm extruder together with a garbage bags normally a 55mm outer layer normally 12-20.

We are producing blown film lines since 1967 and have consistently set new standards such as the development of the internal bubble cooling system and the oscillating haul-off. Bandera Blown Film extrusion range includes. Production of Films Containers and Membranes.

The polymer is melted in an extruder and the hot melt is pumped through a die to form. This shows the arrangement of the different parts of the machine. Blown film extrusion is the most important process for the production of plastic films ranging in thickness from 05 mm to as thin as 5 μm according.

Blown film extrusion is one of the most commonly used thin gauge fabrication processes for manufacturing plastic films in the world. 37 is a schematic of a three layer blown film die 5 and Fig. It is neglected in most models of blown film extru- sion 8 9 10.

Our blown film portfolio offers the right machine for your individual production needs. This allows for a greater solid bed surface area on the barrel wall to keep the viscous energy dissipation via shearing as high as possible. Three Layer ABA Blown Film Machine 30 Stronger Film.

Elements of blown film Film thicness. SmartFlex Blown Film lines 1 3 and 5 layers characterized by a competitive investment level maximized flexibility for different applications recipes power consumption reduction functional and compact layout featuring frames modularity TechnoFlex Blown Film lines for the production. Output Screw LD Ratio Main Motor wInverter Ø45 400mm 600mm 800mm Ø55 Ø65 35kghr 60kghr 75kghr 301.

60 CaC03 Added 100 Recycled Material Used The A-B-A blown film machine consists of two extruders normally of two different sizes. Output Screw LD Ratio wInverter HDPELDPE LLDPEMDPEEVA Ø30 300mm 20kghr 301 EB30MI 75HP EB40MI Ø42 500mm 40kghr 15HP EB45MI Ø45 700mm 50kghr 20HP EB30MIEB45MI ECONOMIC MONO LAYER BLOWN FILM. 350 mm max LF-400 and 550 mm max LF-600 Die orifice.

Though PVC has limited thermal stability it has good melt strength which lends itself nicely to blown film extrusion. FKirk Cantor Blown Film Extrusion 2nd Edition Hanser Publishers Munich Hanser Publications Cincinnati fThe Author. In addition since the melt film thickness over the barrier flight is small the shear energy is also high.

Drawings of multilayer blown film dies. Film Blowing Machine produce Polyethylene filmPolypropylene filmBiodegradable Plastic Filmdecomposed filmPLA filmPVA filmPBAT filmsuit to produce different bagsuich as plastic bag or biodegradable bagPLA bagPVA bagwe can produce different design film blowing machine according to different coutries customers requirement. T h e b l ow n fi l m p ro c e s s.

600 4000mm Die diameter. 08 mm std other sizes available Nip rolls top of tower can be water cooled option Similar basic features to the LF-400 LE-25 blown film line Motorized tower height adjustment is standard. Blown film extrusion is the most important process for the production of plastic films ranging in thickness from 05 mm to as thin as 5.

Auto Loader Hopper Dryer Surface Treater Air Compressor Melt Pressure Gauge Temperature Probe Chiller PB45PB75 PP BLOWN FILM MACHINE Model Screw Dia. μm according to Butler 1. As a result it has good clarity.

Blown film extrusion eliminates some of the problems associated with conventional methods including varying thickness at the edges. Blown Film Basics The goal of this brochure is to describe specific defects that can appear in tubular blown film and to suggest probable causes and solutions. 350 mm max LF-400 and 550 mm max LF-600 Die orifice.

The blown film process is largely used to manufacture pol ymer films. The polymer a polyethylene for e xample is molten.

High Performance Extrusion Machinery Kung Hsing Plastic Machinery Plastic Blown Film Machine

Blown Film Extrusion Line Varex Ii Windmoller Holscher For Hdpe For Pe Multilayer

Film Winder Filmatic O Windmoller Holscher Tube Automatic For Blown Film Extrusion Lines

High Performance Extrusion Machinery Kung Hsing Plastic Machinery Plastic Blown Film Machine

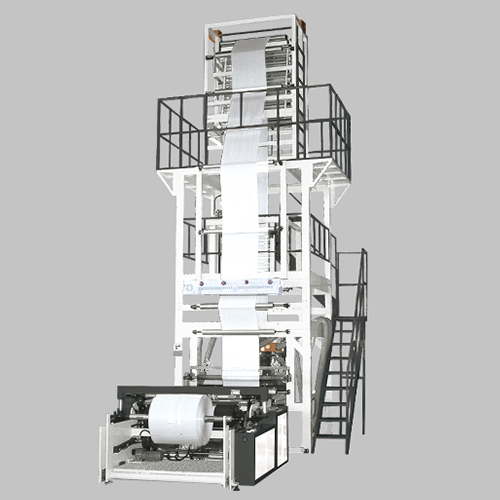

Blown Film Machine Blown Film Line Fki Machinery

Cartoning Machine Designed For Egyptian Customers Factory Design Machine Design Packing Machine

Ocp Ed 209 3d Obj Voennye Transportnye Sredstva Modeli Transportnoe Sredstvo

Wenzhou Aoxiang Packaging Machinery Co Ltd

Wenzhou Aoxiang Packaging Machinery Co Ltd

Wenzhou Aoxiang Packaging Machinery Co Ltd

Pdf Manufacturing And Properties Of Recycled Polyethylene Films With An Inorganic Filler By The Extrusion Blow Moulding Method

Wpc Extrusion Wood Plastic Composite Machine Wpc Profile Extrusion Line Pvc Wood Plastic Machine Wpc Profile Producti Wood Plastic Composite Extrusion Wood

Lung Meng Machinery Co Ltd Prm Taiwan B2b Marketplace

Pdf Manufacturing And Properties Of Recycled Polyethylene Films With An Inorganic Filler By The Extrusion Blow Moulding Method

1 Schematic Of The Film Blowing Process Download Scientific Diagram

Wenzhou Aoxiang Packaging Machinery Co Ltd

Blown Film Bandera Plastics Extrusion Italy

Used Colines Allrollex 1500 Of 2017 For Sale Machinepoint

Feed Screw Manufacturing Rebuilding And Design For Plastic Injection Molding Extrusion Blo Recycling Machines Plastic Injection Plastic Injection Molding